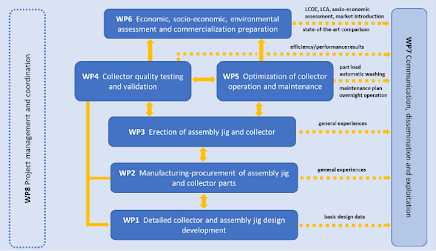

Project structure

The work programme is articulated into 8 interrelated work packages (WPs), led by highly qualified institutions.

WP1

looks at a redesign and detailed engineering of the MSA-Trough in order to adapt the current collector predesign to the final design which can be used for molten salt application. In addition, the automatic mirror washing device will be detailly designed.

WP2

deals with the manufacture, production and providing of all hardware parts necessary for the installation of collector, assembly jig, washing device and connection pipe according to the WP1 design specifications.

WP3

looks at the erection of the MSA-Trough collector and all related components necessary to run the MSA-Trough test facility.

WP4

performs optical, mechanical and efficiency tests of the MSA-Trough. The data and experiences gained about the testing will be used to evaluate the new collector concept to be able to compare the efficiency and quality to other CSP technologies.

WP5

analyzes and evaluates the operation and maintenance procedures of MSA-Trough collectors in order to improve part load operation and to optimize overnight operation by new freeze protection strategies.

WP6

conducts an integrated assessment of the MSA-Trough technology under an economic, environmental and social points of view, in order to get an overall evaluation of the sustainability profile of the novel technology, also in comparison with possible CSP alternatives.

WP7

accompanies the other WPs and ensures that the project outputs and key results are discussed, presented and disseminated in the proper way, thus increasing the project visibility and the replicability of actions

WP8

supports all other WPs by ensuring the best conditions to implement the programme of work, an optimal internal communication, an efficient and cost-effective administrative and operational management, timely delivery of reporting, and a strong interaction with the technical MSA-Trough project committee.